La Chaux-de-Fonds, October 11th, 2023 (10AM CET) – In 2013, Girard-Perregaux unveiled the Constant Escapement L.M., a timepiece that garnered widespread acclaim and clinched the prestigious ‘Aiguille D’Or’ at the Grand Prix d’Horlogerie de Genève (GPHG) in the same year. This model featured a constant force escapement, a mechanism that delivered exceptional rate stability, regardless of the available energy.

The Neo Constant Escapement represents the latest evolution of the Maison’s innovative approach to mastering energy in watchmaking, incorporating a host of aesthetic and technical enhancements. Remarkably, Girard-Perregaux perfected the Constant Escapement in just two decades, a testament to its inventive spirit, especially when considering that it took 250 years to develop the Swiss lever escapement. Furthermore, this new timepiece remains faithful to Constant Girard’s original vision of showcasing the beauty of functional elements but in a contemporary expression.

A Historical Journey and the Birth of the Bridges Collection

In the 19th century, Constant Girard dedicated himself to advancing chronometry, creating highly precise pocket watches equipped with tourbillon escapements. These timepieces quickly gained recognition, earning him numerous awards and prizes. In 1860, he conceived a movement with three parallel bridges, which came to life in 1867 with the bridges made of nickel silver. The pocket watch won a first-class prize at the Neuchâtel Observatory in the same year and remained unparalleled in precision for 17 years. Subsequently, the watch was housed in gold and received a gold medal at the Universal exhibition in Paris.

Girard’s creations were not only renowned for precision but also for their exceptional aesthetic appeal. In 1867, he designed a pocket watch with three prominent bridges, effectively transforming these functional components into artistic elements. In 1889, the three bridges were crafted in gold and further stylized, giving birth to the iconic three bridges design language that endures to this day.

While Girard-Perregaux takes pride in its heritage, it does not dwell in the past. In 2014, the company introduced the Neo Bridge, featuring elaborate, CNC-machined sinuous bridges that can be presented individually or as a trio of architectural forms. The Bridges collection showcases a blend of classical and contemporary timepieces, demonstrating Girard-Perregaux’s versatility and expertise.

Clémence Dubois, Chief Marketing Officer of Girard-Perregaux, remarks, “The Bridges collection is one of the oldest mechanical signatures in watchmaking and is an important pillar of our Manufacture. Since 1867, the bridges have continuously evolved in terms of shapes, materials and finishes. However, this latest addition to the collection, the Neo Constant Escapement, is unequivocally neoteric and, courtesy of its revolutionary Constant Escapement, sets a new standard in terms of chronometry.”

The Significance of the Name

As previously mentioned, the name Neo Constant Escapement distinguishes this model as contemporary and emphasizes the movement’s unique ability to provide a constant force to the regulating organ. Furthermore, the watch’s name pays tribute to Constant Girard, the man who dedicated his life to advancing chronometry.

Understanding the Control of Time’s Flow

The intricate dance of forces within a watch movement must be controlled to ensure accurate indications and reliable operation. A tensioned mainspring in a spring barrel serves as the energy source for the various dial indications. This energy is transmitted through a series of gears (the gear train), allowing the energy’s magnitude to be adjusted, similar to an electrical transformer, reducing the energy to the desired level.

Connected to the gear train, the escapement provides impulses to the regulating organ, allowing the escapement to unlock and move the hands a defined amount before locking again. This cyclic process governs the “flow of time.”

Constant Force Mechanisms

Most watches face a challenge where the force from the spring barrel, supplying the regulating organ, can be excessive when fully wound, potentially affecting precision and causing damage. Conversely, as the energy in the barrel depletes before complete exhaustion, the regulating organ may receive insufficient force, leading to imprecisions. This situation can be visualized as a diagonal line on a graph representing force over time. Ideally, the force reaching the regulating organ should be linear, resembling a continuous flat/horizontal line on the graph. Without a constant force mechanism, the period of optimal precision is relatively short.

In Haute Horlogerie, watchmakers have long strived to maintain uniform energy delivery to the regulating organ, often referred to as “constant force.” Various mechanisms have been employed, such as the fusée and chain, Geneva stopworks, and remontoir d’égalité, all distinct from the escapement.

A constant force mechanism ensures the watch’s rate remains stable, an essential feature for chronometric performance. However, it’s crucial to note that the Neo Constant Escapement is a certified chronometer (COSC), independently confirming its timekeeping excellence, reminiscent of the Manufacture’s pocket watches submitted for chronometer testing in the 1860s, which won the Neuchâtel Observatory Centenary Prize.

Examining the regulating organ (the balance and hairspring), the balance wheel oscillates back and forth, each swing called a beat, with the amplitude representing the swing’s magnitude in degrees. Typically, when the force decreases, the amplitude drops, resulting in a slower movement.

An Ingenious Approach to Achieving Constant Force

In contrast to traditional constant force mechanisms, the Neo Constant Escapement adopts a unique approach. This watch employs an ingenious silicium blade to ensure the balance’s amplitude remains consistent, regardless of the energy stored in the barrel.

Matthieu, a skilled watchmaker in Girard-Perregaux’s R&D department, spent over a decade perfecting the Constant Escapement, creating prototypes, refining specifications, and securing numerous patents. This development journey involved honing the constant force device, taking it from a laboratory concept to a technology suitable for series production.

After years of research, Girard-Perregaux presented a concept watch in 2008, incorporating the innovative silicium blade. This technology evolved and led to the production version of the Constant Escapement L.M. in 2013, which received the prestigious ‘Aiguille D’Or’ at the GPHG.

The Birth of the Silicium Blade: An Inventive Train Journey

The idea for the silicium blade was conceived during a train journey, as an inventive watchmaker held a train ticket between his fingers, making intriguing observations. When the train ticket was bent, it formed a ‘C’ shape and became unstable due to lateral pressure, accumulating energy uniformly until reaching a point of instability, at which it snapped back, creating an inverted ‘C’ profile. This dynamic transition from compression to bending formed the basis of the Constant Escapement’s operation.

Unlike conventional watches, the Neo Constant Escapement movement includes a ‘fifth wheel’ connected to the gear train. This fifth wheel transfers energy to two escape wheels, each with three teeth, matching the movement’s frequency (3Hz). Energy is received alternately from the escape wheels, not simultaneously. Subsequently, a rocking lever transmits the energy to the silicium blade, which utilizes the elastic and bi-stable properties of the blade to deliver impulses to the balance wheel. This intricate dance includes 20 sequences per oscillation, ensuring constant force and consistent amplitude. The blade’s symmetrical shape and the positioning of the escape wheels on either side of the balance wheel ensure the forces act at the center of the regulating organ, delivering smooth, unimpeded rotational motion.

This unconventional and highly inventive configuration offers remarkable rate stability and chronometric performance.

The Watchmaker’s Vision Realized

When the inventive watchmaker sought support for his idea, Luigi Macaluso, then Chairman of Girard-Perregaux, was receptive and eager to back the inventor’s dream of making the Constant Escapement a reality.

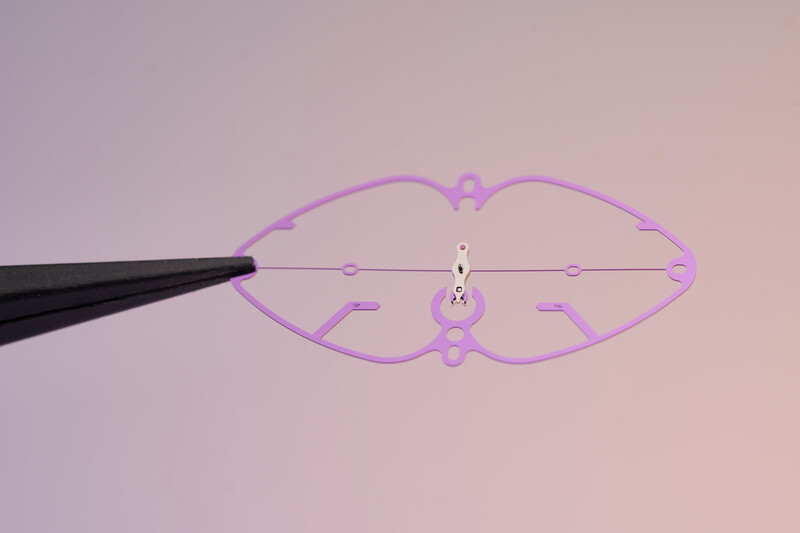

An Ultra-Thin Silicium Blade Enabled by DRIE

The development of Deep Reactive Ion Etching (DRIE) in the 1990s provided Girard-Perregaux, in collaboration with specialist firm Sigatec, with the means to create the silicium blade. This blade is astonishingly thin, measuring just 14 microns, six times thinner than a human hair.

Sigatec, founded in 2006, is a trusted partner of Girard-Perregaux and a leading producer of silicium components for the watch industry. Sigatec is jointly owned by Sowind Group (Girard-Perregaux’s parent company) and Mimotec, a prominent name in UV-LIGA technology.

Sigatec’s production facility features a clean room where parts are manufactured in a controlled environment to mitigate the risk of product contamination. The specialist firm conducted numerous product trials, experimenting with different shapes, coatings, and sizes to achieve the perfect result.

Silicium is extracted from silica using electrometallurgy and then formed into highly pure silicium crystals. This cutting-edge material is lightweight, corrosion-resistant, and frictionless, making it ideal for watchmaking. Silicium can be shaped into intricate forms not achievable with traditional milling or stamping techniques. In the case of Girard-Perregaux, the high elasticity of silicium is exploited, allowing the blade to repeatedly buckle and provide a constant force to the balance.

The Silicium Blade Manufacturing Process

The creation of the silicium blade takes place in a controlled laboratory setting. A large silicium crystal is cut into thin discs called ‘wafers.’ Photolithography is used to impart geometric shapes onto the wafers.

- The silicium wafer is bonded to a silicium support using an oxidation layer. The depth limit of the material can be determined during the subsequent etching phase.

- While rotating the wafer at high speed, a liquid polymer called ‘photoresist’ is applied to the surface. The centrifugal action displaces excess liquid, leaving a smooth, thin, and uniform layer of the resin material.

- A mask, shaped like the escapement spring, is placed on top of the wafer, and the entire assembly is exposed to intense UV light. A chemical reaction occurs, followed by the use of a special solution to remove any residual photoresist.

- After cleaning, the wafer reveals a series of escapement springs, which are cut from the wafer using the DRIE etching process. This technique, effectively reverse 3D printing, removes silicium and resin layer by layer until reaching the oxidation layer.

- The silicium support and oxidation layer are removed through a ‘stripping’ process. Subsequently, the wafer undergoes thermal treatment, creating an oxidation layer on the silicium components, improving their mechanical resistance and imparting a distinctive color, transitioning from blue to purple in this instance. Each escapement spring, with its central buckling blade, is carefully detached by hand from the wafer.

- The resulting escapement spring is 120 microns thick, with the blade measuring a mere 14 microns wide, while a human hair typically ranges from 50 to 90 microns in thickness.

- Notably, the production of the Constant Escapement with its unique silicium blade allows for only 30 escapement springs on a single wafer, compared to 500 pieces for conventional hairsprings, increasing production costs.

A New Design Language with a Familiar Approach

The Neo Constant Escapement possesses a unique design that sets it apart from other watches, yet it shares some genetic elements with contemporary members of the Bridges collection. The dial is positioned under a sapphire crystal ‘box,’ inviting light to illuminate the display and offering side views of various dial components.

In contrast to the 2013 Constant L.M., which featured an off-center dial for hours and minutes, the Neo Constant Escapement has central hour and minute hands. These hands are skeletonized dauphine style, treated with rhodium, and feature luminescent material for visibility in low light conditions. The flange of the watch boasts a black track with white markings and prominent luminescent hour markers that extend outward, creating the illusion of floating above the main dial area. Additionally, the watch includes a central sweep seconds hand with a sky-blue tip and an arrow-shaped counterweight, a nod to Constant’s famous gold bridges from 1889.

The Neo Constant Escapement introduces a new design approach to watchmaking. Housed in a Grade 5 titanium case, the timepiece is lightweight, attractive, and surprisingly wearable, given its mechanical complexity. The movement, particularly the escapement spring with its unique buckling blade, serves a functional purpose while contributing to the watch’s aesthetic allure. The use of black PVD and anthracite NAC treatments for the movement delivers a modern appearance with ultra-refined finishing inspired by Haute Horlogerie.

A linear power reserve indicator at 9 o’clock reveals the energy stored in the twin barrels, with the Calibre GP09200 boasting a minimum 7-day power reserve. The Neo Constant Escapement allows partial views of the motion works, extending to the escapement spring, balance, escape wheels, and more.

The Neo Bridge

The escape wheels are supported by two independent bridges in a sleek black finish, each secured with a gleaming screw. These bridge designs draw inspiration from the famous 19th-century bridges but are executed with a modern twist. Underneath, a separate Neo bridge spans the base of the dial, supporting the balance wheel.

A 45mm Case in Grade 5 Titanium

Crafted from Grade 5 titanium, the case measures 45mm in diameter at its widest point, making it more compact than its predecessors. The case’s sides taper inward, both toward the sapphire crystal ‘box’ and near the sapphire caseback, reducing the dimensions to a modest 42.5mm in narrower areas.

Grade 5 titanium is chosen for its lightweight, corrosion resistance, strength, and hypoallergenic properties. However, its exceptional hardness makes it challenging to machine. In the Neo Constant Escapement, the lugs, bezel, and case are all carved from a single piece of this alloy, adding to the complexity of the case’s production. The watch’s polished and satin-finished surfaces, both straight and circular, contrast beautifully and are especially remarkable given the alloy’s extreme hardness. This contrast extends to the fluted crown.

The Calibre GP09200

The watch’s reverse, visible through the sapphire caseback, offers a closer look at the hand-wound movement, the Calibre GP09200. The symmetrical design of the dial carries over to the movement, with twin barrels at the top and two Neo Bridges at the base. The silver-toned gear

train stands out against the black movement components. The rear of the escapement spring, escape wheels, and balance wheel can be observed up close, allowing the wearer to appreciate the movement’s ultra-refined finishing.

A rubber strap secures the Neo Constant Escapement to the wrist, featuring a fabric effect and a titanium triple-folding buckle with micro-adjustment for optimal comfort.

Continual Innovation

An innovative mindset has long been a hallmark of Girard-Perregaux. The Maison embraces innovation, envisioning new mechanisms to advance horology. The Neo Constant Escapement is no exception, incorporating several new technologies. Approximately 30% of the patents used in this model, a total of 13, are new. The new movement features fewer components than the 2013 model, with 266 compared to the previous 280, a clear example of optimizing complexity.

Some of the patents employed include “Improvement of the power reserve and efficiency of the escapement,” “Improvement of the chronometry and the efficiency of the balance wheel,” and “Complete angular locking of all sequences of the escapement.”

Girard-Perregaux plans to file additional patents covering various additional innovations, including the geometry of components that facilitate the automatic starting of the movement and the shape of parts that enhance the efficiency of the escape wheel.

The Neo Constant Escapement: A Tribute to Constant

Since 1791, Girard-Perregaux has thrived thanks to the hard work and inventive ideas of many individuals, but one individual, in particular, has left an indelible mark on the Maison: Constant Girard. A highly gifted watchmaker, Constant united mechanics and aesthetics, leaving a legacy that remains relevant today.

The Neo Constant Escapement upholds the Maison’s heritage, combining mastery of energy with a unique aesthetic that respects the past while embracing the present and the future.

Patrick Pruniaux, CEO of Girard-Perregaux, comments “The Constant L.M was a remarkable watch, something that was recognised with the award of the GPHG ‘Aiguille D’Or’ in 2013. It is now part of our Maison’s patrimony, however, we did not want to leave it on the shelf gathering dust. On the contrary, we wanted to build on our know-how, push the performance envelope and make an up-to-the-minute evolution of the original concept. The Neo Constant Escapement is superior in every way. It stands testament to the dedication of our talented team and represents a new era in watchmaking.”

The Neo Constant Escapement will be available for purchase in January 2024 and will be offered at authorized Girard-Perregaux retailers worldwide. Due to the complex production process, the Neo Constant Escapement will be produced in limited quantities, ensuring a high degree of exclusivity.

For more information, please visit Girard-Perregaux.com.