Tissot T-Touch Connect Sport: Harnessing Solar Power with Swiss Precision

Situated in Le Locle, Switzerland, the Tissot T-Touch Connect Sport represents a fusion of solar technology and impeccable Swiss craftsmanship. Functioning as a solar-powered timepiece, it embodies durability, self-sufficiency, and a commitment to authentic watchmaking. The culmination of extensive development efforts over several years, this watch seamlessly integrates solar cells with the artistry of Swiss watchmaking.

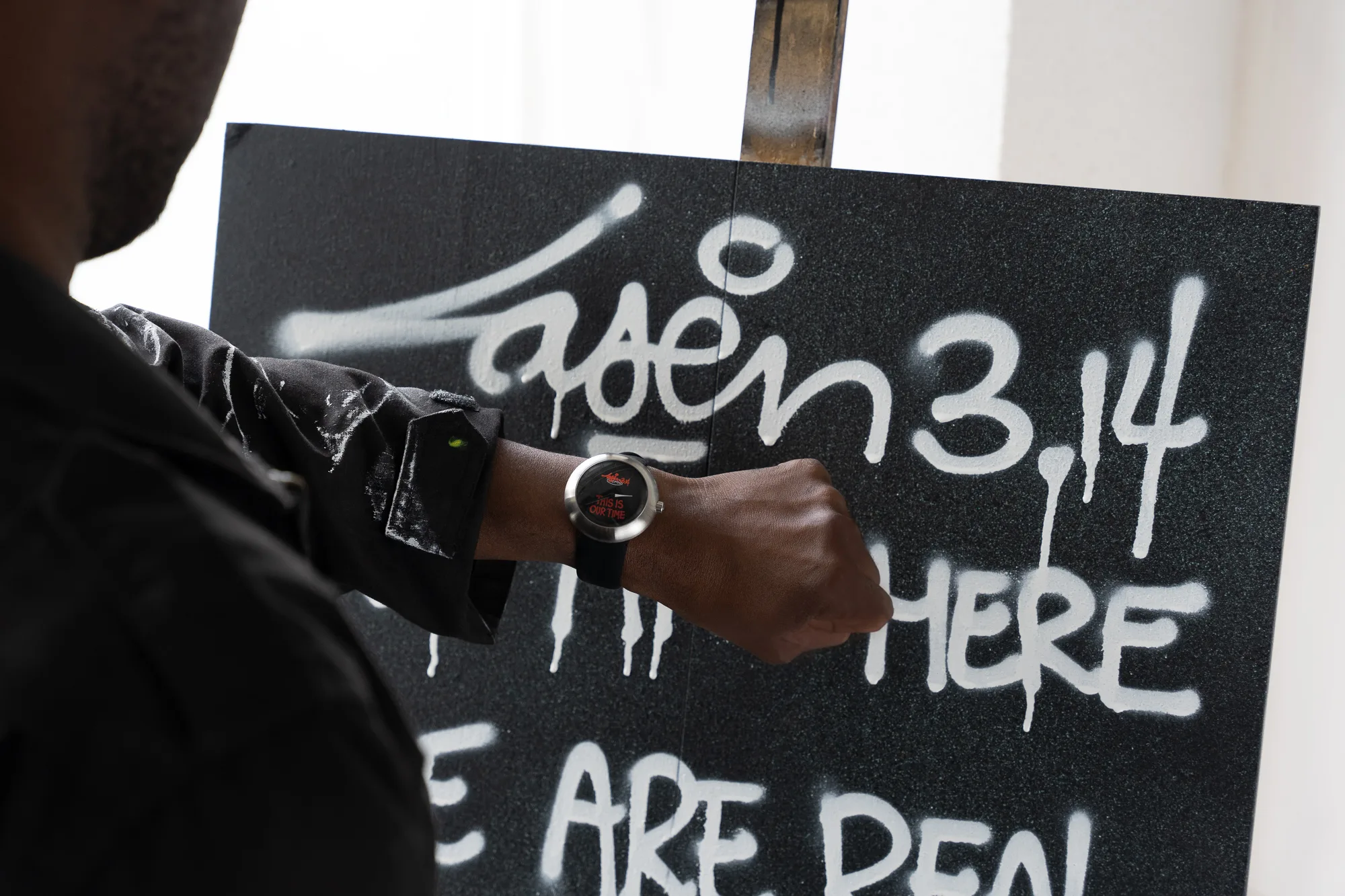

Catering to both sports enthusiasts and watch aficionados, the T-Touch Connect Sport seamlessly blends practical functionalities with a sleek design. Its precision, extended autonomy, sporty features, and capability to run for months without interruption ensure that wearers remain in sync with both the passing time and their personal goals.

Key to the watch’s innovation is the incorporation of photovoltaic cells. Manufactured using a blend of materials including glass, silicon, zinc oxide, aluminum, silver, and resins, each solar cell provides an energy equivalent to five button batteries annually. Crafted by Nivarox-FAR, a Swatch Group company, these photovoltaic cells excel in low-light conditions, setting a new standard in Swiss watchmaking. The sophisticated design seamlessly integrates the photovoltaic cell into the watch dial, eliminating the need for semi-transparent decorative dials.

The production process begins at the Front-End, where a glass wafer undergoes coating with a stack of thin films, including a transparent front contact, a thin film silicon diode, and a metallic back contact. Patterning, involving high-power and ultra-short laser pulses, etches the solar cell design into the silicon. The Back-End phase incorporates techniques such as drilling and laser dicing to ensure the solar cell’s resilience to shocks of up to 5000G. Rigorous visual and electrical checks are conducted to assess performance under various lighting conditions.

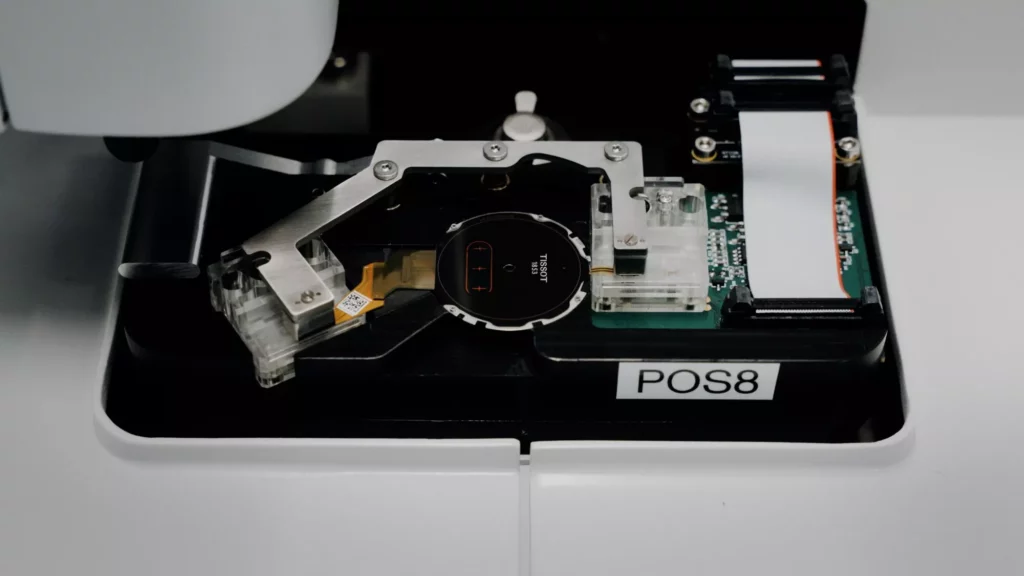

For AMOLED integration, EM Microelectronic, another Swatch Group company, lends its expertise. A flexible connection cable is applied to the Solar Cell dial, ensuring electrical connectivity through bonding with “ACF.” Subsequently, an AMOLED display is attached using a transparent optical resin, enhancing contrast, mechanical robustness, and preventing particle intrusion. The fully automated, high-precision optical bonding is followed by the addition of a metal support, preparing the dial for integration into the final watch. The AMOLED and solar cell module undergoes meticulous functional testing, ensuring quality through a variety of test patterns and a “Sun Test” simulating different lighting intensities. The process concludes with a final visual inspection by expert watchmaking-level operators, ensuring only flawless dials make it to the final watch assembly.

In today’s context, advancements in solar technology are of paramount importance. As global discussions revolve around sustainability and energy efficiency, innovations like the Tissot T-Touch Connect Sport are not merely desirable but crucial. Its autonomy, powered features, sporty design, and Swiss Made origin establish a new standard in watchmaking—a technological marvel paving the way for a more sustainable future in horology.

For more information, please visit TissotWatches.com.